I was lucky to spend 4 beautiful years with a Creality Ender 3 v2 that I modded to the brim and never failed to deliver quality prints. I never had to adjust, calibrate or tweak anything regarding print quality.

I upgraded today to a Sovol SV-08 because despite its qualities, the Ender 3 is too small and slow for my current needs.

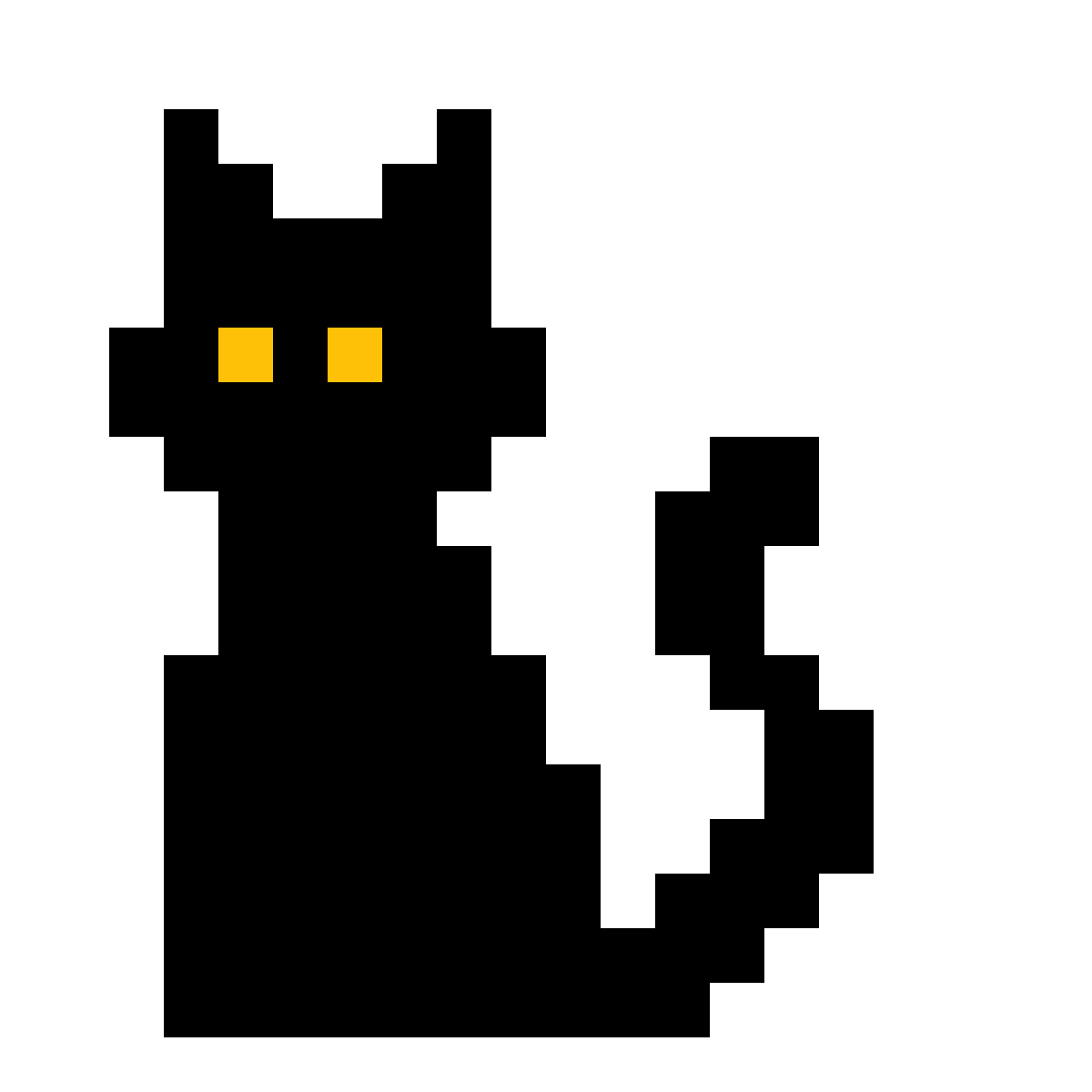

However, the print quality is definitely not there (yet). Overhang quality is bad but I think I may be able to tweak it with filament temp and/or cooling. There’s a bit of ringing but I can live with it. My main issues are the large holes in the hull.

Filament: Overture black PETG, 240°C, 24min print.

What should I try?

Thanks

Edit: most issues were solved by doing the following adjustments:

- PETG temperature increased to 245

- volumetric flow reduced from 17mm^3/s to 10mm^3/s

- manually adjusting z-offset with the paper sheet method like on my old Ender3

There are still minor issues like overhang drooping and adhesion needs a bit more work but quality is now almost on par with my previous printer.

Thanks to everyone !

Nice cheat sheet!

Weirdly enough, I printed at 235 thinking the nozzle was too hot and it was worse. At 245 more issues seem to disappear except less than ideal overhangs.

I believe I was printing Overture petg around 250 on a brass nozzle, I do around 270 stainless and it’s fantastic. I run a dual 5015 satsana duct (v2 with removable ducts) and keep the fan speed fairly low which seems to help get the airflow perfect

Here is a comparison between an old benchy done with my Ender-3 and three with the SV-08

I highly recommend Teaching Tech’s 3D Printer Calibration site. Some of it will not apply to your SV08 and some of it you will have to adjust to work with your printer, but it is a great overall step-by-step process with tools to generate various test models for tuning specific aspects of print quality.

I ran the printer’s pre-sliced 12-minute benchy with cheap Geeetech PLA filament, and it didn’t come out great, but then realised that when I’d removed the nozzle clog that was there from the factory (apparently they test some nozzles during QA, so mine had some dregs of filament with a lump that needed a cold pull to shift it) I’d accidentally plugged one of the part cooling fans into the wrong header and it wasn’t running. After fixing that, it came out much better than what you’ve got here, despite a pause part way through due to trying to do it with the tail end of a roll.

I’ve read that the throat cooling isn’t great for PETG as the fan as it draws warm air from inside the toolhead shroud, and there’s an alternative one on printables that avoids this problem (although a duct to isolate the fan and its cutout in the shroud from the rest of the shroud interior might be simpler), so that could be related as you’re running PETG.

Thanks for the lead! That might be it, I saw a big blob of goop leaking from it the first time I heated it. I’ll rebuild the hotend when I have time. There an extra nozzle in the kit.

Edit:

Here is a comparison between an old benchy done with my Ender-3 and three with the SV-08. The surface finish with the Ender 3 is much more consistent and the PETG is a lot shinier. Maybe speed is a factor too. Shoud I try and slow the SV08 down a notch?

I’ve definitely noticed less shininess than the same filament was getting at the same temperatures on my previous printer, except for the first layer. As the first layer prints without part cooling, my guess is that the extra part cooling versus the other printer means it’s setting before it’s had time to self-level. If that’s right, then turning down the part cooling (and then also the speed so you can get away with the reduced part cooling) would make things shiny again. I’ve not bothered investigating that, as most of what I print is either functional, where I wouldn’t care about shininess, or gets painted, where any shininess would come from paint or clearcoat.

I can not see the holes you are talking about. Could you provide pictures of those defects specifically?

deleted by creator

Whatever u want. I made myself a phone case wirh tpu that is objectivly better than anything u can buy

I think OP is asking for help with what to try next to fix the issues on the benchy, not what item to print next.

Ahh, looks like hes got some layer shift and bridging looks like it has some iaaues. I recon op needs to boost his cooling fan a little to fix the bridging issue layer shift could be a multitude of issues tho. What printer is it?

Buddy get some sleep then reread the post lol