So I just picked up this 12"×6"×10’ maple beam at an auction today and had to chop off two feet of it to fit it in my car. I’m thinking of making a couple end-grain carving boards for friends with what was cut off.

I’m tentatively thinking of just slicing it into 2" cookies and gluing them together, but I’ve never seen a cutting board like this that wasn’t a collection of like 1" pieces glued together. Is there any reason not to use larger pieces when gluing up a cutting board? Thanks in advance

The only reason why cutting boards are often thin is cost. A thicker cutting board will be more resistant to warping. I encourage using thicker pieces.

I don’t think I’m describing my question clearly. I’m imagining a 2" thick cutting board made up of 4, 6"×12" end grain slices from the beam.

Every end grain cutting board I’ve ever seen is comprised of many individual pieces from like .5"×.5" up to like 2"×2" at the largest.

Is checking the only risk from using very large pieces, like I want to?

Oh, I haven’t got a clue about the risks of that. I’m sorry I can’t be more help. Good luck and know that I’m cheering you on!

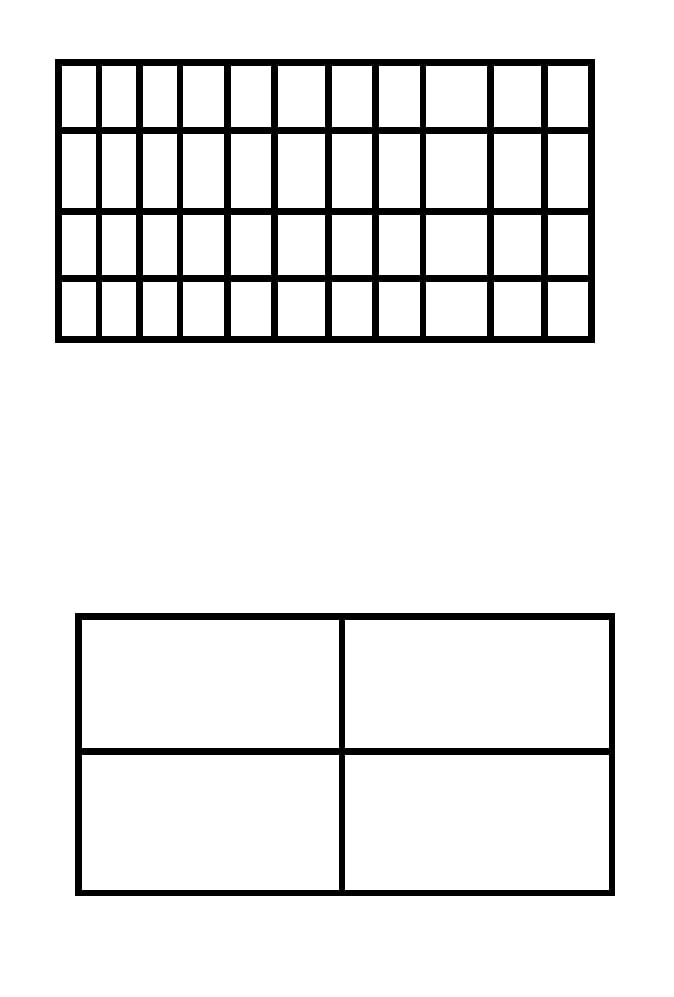

Something you can do is to alternate the grain pattern to prevent cupping and bowing (like what is done with a table).

If you’re looking at the cutting board from top down (and rotated 90 degrees):

( )

) (

With each bracket representing the grain pattern.