- cross-posted to:

- 3dprinting@lemmy.world

- cross-posted to:

- 3dprinting@lemmy.world

On a post a while back I made a comment about nobody making an Axis or crossbar locking knife with a CQC style pocket hook opener on it.

This is what’s known as “making a call-back.” It establishes a sense of continuity with the reader, which makes them feel good about remembering something you said earlier and gives them a sense of belonging or membership in the community surrounding the brand you’re building. See what I did there?

Yes, okay, I’m beating around the bush. You all read the title and saw the headline picture. You know what time it is.

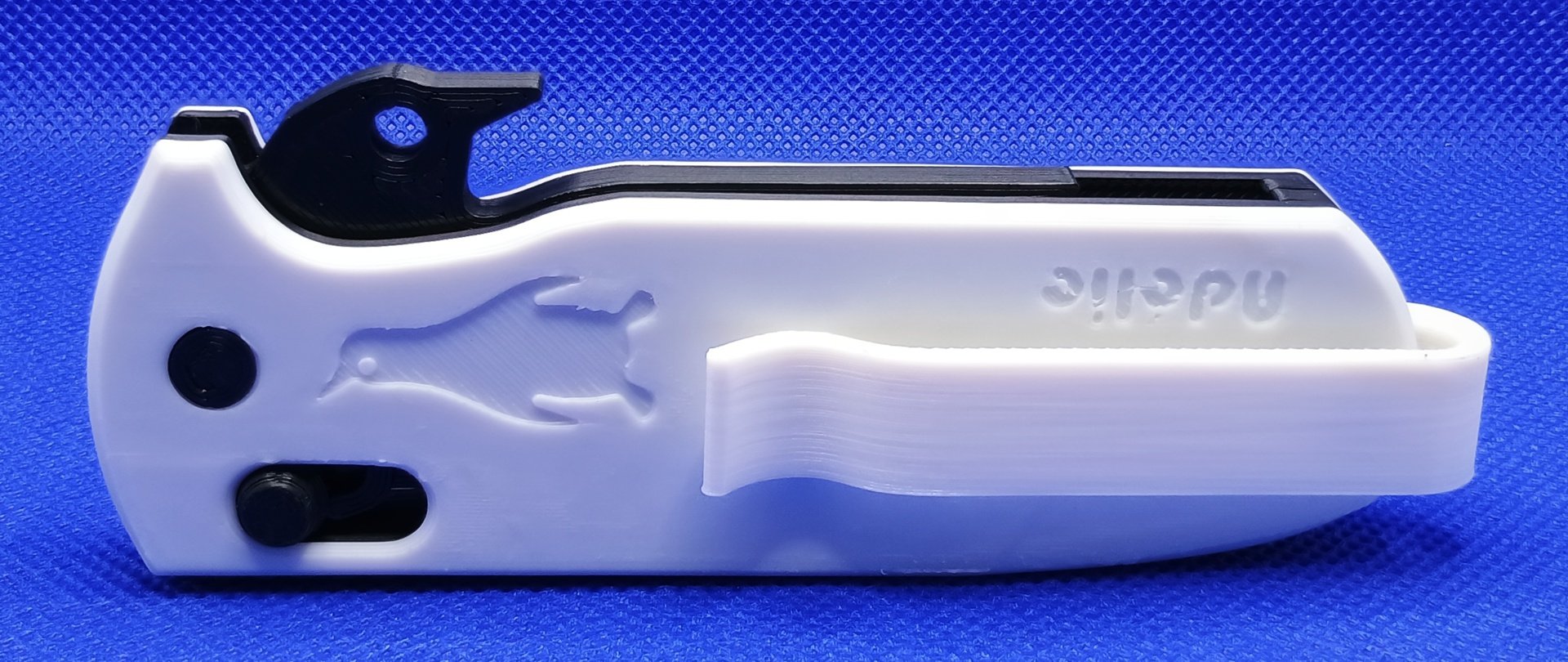

Noot noot, mothercluckers. This is the Adélie, and it’s exactly what I said it was. If you’ve been wondering why my output has been so slow lately and what the hell I’ve been working on instead, now you know.

And it’s fully 3D printable. Well, except the blade, of course. You can grab the Printable here.

The Adélie employs the same design philosophy as my previous two knives, in that it is a printable design that can be produced as-is, requires no supports, and does not rely on any external hardware. Except, again, the blade.

And if you don’t mind my saying so, I think it’s also pretty rad.

Our reference example is provided in this boss black-and-white penguin color scheme. Boss, that is, except for the fact that photographing a snow white object on my usual white background void while keeping it acceptably visible actually turned out to be literally impossible. Sometimes I’m just really fuckin’ smart, aren’t I?

So today you get blue. And you also get to see why I never use any of the various colored background swatches my photography box came with, because they’re terrible. I’m not even going to try to edit the backgrounds out of these photos. So much for consistency in building that brand.

At its core, the Adélie has a truly functional Axis lock/crossbar lock mechanism. Of course it requires no external springs; the necessary spring action is provided by a pair of flexible prongs built right into the model.

I also incorporated a lot of tricks and mechanical improvements over my previous models, all of which I learned the hard way, and which I will now be obligated to eventually backport to those designs now that I’ve finished this one. Eventually. Give me a minute, okay?

Let’s start with the screws. The biggest weakness of my last two models was easily the printed screws, which had the unfortunate but unavoidable capability of being able to cleave themselves in two via the sheer mechanical advantage afforded by their threads. It turns out that Archimedes guy was on to something after all. The upshot is, and some of you probably found out, if you put any torque whatsoever on the old screw design after they reached the point of bottoming out, the heads would just ream right off.

The solution to this turned out to be to make screws that just… don’t have heads. I don’t know why I didn’t think of it sooner.

“That clearly would not work,” you say. Well, yes, that is unless every single part that the screw goes through is meticulously designed with a single uninterrupted helical thread all the way through the entire assembly.

Let’s talk other features.

The Adélie has a fully reversible, deep carry pocket clip.

It also has the aforementioned Emerson/CQC style pocket hook on it for snappy automatic deployment when you draw it, by way of snagging just so on the hem of your pants as it clears the fabric.

You know what? It occurs to me that for all the times I’ve yammered about the damn Emerson Wavetm CQC pocket hook opening action, I’ve never displayed how it actually works.

That’s how it works. Fast, clean, elegant. But this isn’t the Wavetm, because even though Emerson’s patent on that expired in 2017, its shape and name are still trademarked. So this is the Penguin Opener.

If you feel like it, you can also use the penguin’s beak to open the knife manually with your thumb. I was actually going to put a thumb stud through him, but I determined throughout my testing of various designs that it actually wasn’t necessary.

And of course Benchmade’s Axis lock patent expired in 2016, so along with every other knifemaker in the world I stole that, too. Surely, though, a plastic 3D printed knockoff of the same cannot be opened with the “Axis flick.”

Wrong.

The Adélie has a bushing pivot system. That’s design improvement #3. The net result of that is that you can cleanly flick it both open and closed, although owing to the blade carrier’s very light weight it takes a bit more finesse than with a commercial knife that’s made of… you know, metal and stuff.

The CQC-6K comparison is a bit more on the nose today than usual. The Adélie is 6-5/16" long when open, including the protrusion of the clip at the rear. The blade carrier protrudes 2-1/2" from the forward end of the handles, but the exposed portion of the edge is 1-1/8" long. Of course, it takes standard Stanley style utility knife blades which are available in a variety of styles and guises…

…Including these zooty ceramic ones, which with one installed renders the Adélie completely nonmetallic. Make of that what you will.

Fully assembled and with a regular metal blade in it, the reference example weighs just 27.9 grams or 0.98 ounces. Ultralight backpackers, eat your hearts out. Of course, as a non-commercial product you print yourself, the weight will be influenced by what infill percentage you make it and what material or material(s) you print it out of. Maybe some of you have rhodium-infused PLA filament or something to make the blade carrier heavy. I dunno.

It’s a bit longer than the Gerber EAB pictured at the bottom, by necessity. The EAB is made of metal, and it does not require any length to be spent on having a tail screw since the body is a unitary machined piece of steel.

I’m including a disassembly pic with the complete bill of materials just because I got it for free, so to speak. Usually I have to disassemble the knife in question to get this photo, but in this case the Adélie comes disassembled to begin with, all in bits already right off of your print bed. Assembly is, of course, required. I’m not going to go into that here – this screed is going to be quite long enough already – but it is all detailed on my Printables post.

It’s not serious engineering, this, but some design work did go into the Adélie.

On my previous knives, my screw design was deliberately designed to be operable with a penny, rather than real tools, just to be cheeky. That’s not really an option here. With the same single narrow diameter down their entire length, the screws I designed don’t quite have the surface area on the head to accept the curvature of a penny’s edge. So I had to cast around for some other suitably ridiculous yet readily available tool to match up with.

Ultimately I settled on this, which is one of those promotional giveaway screwdrivers. This one is from the Sloan Valve Company in Franklin Park, Illinois and I’ve had it since at least the 1980’s.

I have oodles of these damn things, and so does anyone else who’s been around for a couple of decades. They are precisely the sort of goofy thing that’s not quite a real enough tool to actually be useful for much of anything else. I suppose you could also use a normal purpose-built quality screwdriver to assemble your Adélie if you felt like it, but… come on.

I will also leave you with some of the prototype builds I produced while messing around with various tweaks to the mechanism and overall profile.

Now all the internet lost media historians can remain forever wistful over what could have been, rather than what we ultimately got. (For instance, I’m particularly partial to the one with the angled tail and offset rear screw, but it didn’t play nice with the pocket clip design so that profile wound up in the bin pretty early on.)

Conclusion: If you want to get your hands on your own one of these, you can download the model files from here.

Unrelated but the company I work for used to buy Sloan products by the thousands back when they also made parts for a very different industry than bathrooms.